Four Differences between Fine Punching and General Punching

Many people may not have been exposed to precision stamping, so don't panic. Let's read today's article with three questions: What, Why, and How, to see what precision stamping is and what is the difference from ordinary stamping.

01 ABC Sharing Meeting - What is Jingchong

Fine Blanking, also known as precision punching, originated from ordinary stamping. When we have high precision requirements for the cross-sectional smoothness of stamped parts, ordinary stamped parts cannot meet the high cross-sectional accuracy requirements. Therefore, people have found a stamping method to control the cross-sectional accuracy, which is called precision punching. Simply put, precision punching ≈ stamping+cold extrusion. Under the premise of equivalent quality, precision punching is a low-cost alternative to machining, powder metallurgy, and other processes due to its high processing efficiency.

Working principle of precision punching

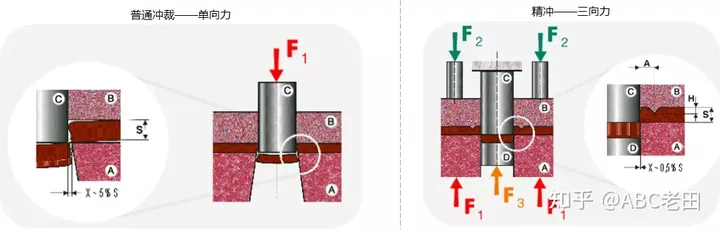

Everyone has experience in tearing paper. Under pure tensile force, cracks will freely extend and the resulting cross-section is generally serrated; If scissors are used for separation, the upper and lower parts of the scissors generate pressure on the separation area of the paper. The separation section is strictly generated in a neat manner according to the direction of the scissors, and fine punching is also the same principle. Due to the softness of the paper, the upper and lower scissors structure can easily transmit pressure to the entire shear area. However, as a metal, due to its high hardness, special mechanisms must be used to effectively transmit pressure to the entire shear area. The most common is the precision punching structure of the gear ring pressing plate shown in the right figure below.

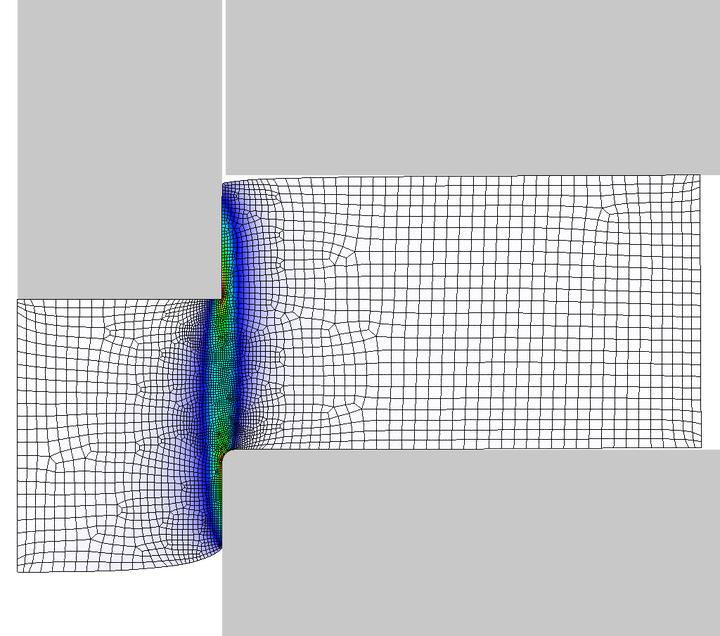

The principle of precision punching process for gear ring pressure plate is that a three power press acts on the processed material, applying three direction compressive stress to the processing area, so that the deformation area of the material is completely in a compressive stress state during the separation process. From a microscopic perspective, when the relative motion of the material structure separates, the slip motion at the grain boundary cannot be extended arbitrarily due to the effect of compressive stress (the grain boundary separation motion is not restricted and can be freely extended, resulting in cracks), but is strictly limited to a very small gap area between the convex and concave molds, sliding along the direction of the punch. From a macro perspective, a neat separation section, namely a fine punching section, is generated.

So, the essence of precision punching is that the material separation area always maintains a compressive stress state during the separation movement process.

The process of precision punching is the process of controlling compressive stress.

Let's take a look at a dynamic diagram to deepen our understanding of precision punching. Remember the following four steps:

- The first step is to press the gear ring.

- The second step is to punch and reverse press the material.

- The third step is punching and separating.

- The fourth step is to compress the air or separate the material belt from the product and waste by the mechanism.

02 ABC Sharing Meeting - Differences between Fine Stamping and Ordinary Stamping

Fine stamping originated from ordinary stamping, but it is not as simple as the reinforced version of ordinary stamping. The essential difference between precision stamping process and general stamping process is that ordinary stamping cannot effectively avoid the occurrence of cross-sectional tearing during punching, while precision stamping tries to suppress the occurrence of sheet tearing during punching. Let's compare the differences between precision stamping and ordinary stamping from two aspects: workpiece characteristics and mold structure.

Differences in requirements for processed materials

Ordinary stamping can process almost any material, as long as the strength of the mold steel is sufficient and the pressure of the press is sufficient.

But for materials used for precision punching, in order to effectively transfer compressive stress between material crystals to suppress cracks, the processed material needs to have good plasticity, low yield strength ratio, and high elongation; It is necessary to have a good organizational structure, and uneven material organization is difficult to produce uniform inhibitory effects under constant pressure conditions; Usually, the tensile strength needs to be below 600MPa~700MPa, and materials that are too hard usually have a coarse microstructure (such as martensite). When selecting materials, you can choose based on the following three conditions:

- When the carbon content of the material is less than 0.35%, it can be directly precision punched.

- When the carbon content (carbon equivalent) of the material is 0.35%~0.7%, spheroidizing annealing is required.

- High strength microcrystalline grain alloy steel can be chosen.

Common materials

- Low carbon steel: DC03, DC04, etc

- Low alloy high-strength steel: H420LA, S500MC, etc.

- Quenched and tempered steel: 16MnCr, 42CrMo4, etc.

Differences in processing capability characteristics

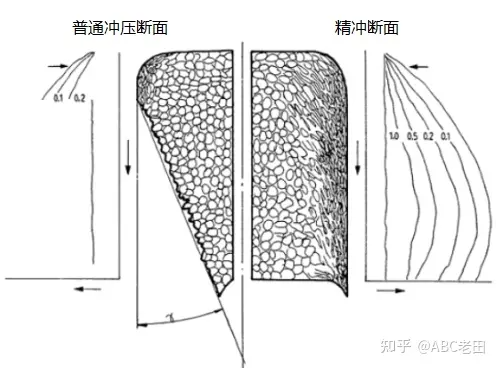

The following figure shows the cross-section of ordinary stamping and precision stamping, and it can be seen from the appearance that these two are completely different. Let's compare these two stamping processes from the details below.

General punching limit size

Pu Chong: The minimum aperture is 1.5 times the material thickness.

Fine punching: The minimum aperture can reach 0.6 times the material thickness.

dimensional accuracy

Pu Chong: General dimensional accuracy, IT14. Fine punching: High dimensional accuracy, IT6-9.

Flatness

General punching: up to 0.1mm per 100m ².

Fine punching: up to 0.01mm per 100m ².

Section perpendicularity

General punching: approximately equal to the punching gap, with a material thickness of about 10%.

Fine punching: 0.003mm per 1m ², with a tilt of less than 1 °.

Cold work hardening

Pu Chong: Cold work hardening of section collapse angle and bright zone.

Fine punching: Full section cold work hardening can improve the strength of the contact surface.

burr

General punching: The burr is small, and the allowable value is generally 10% of the material thickness. There is no special requirement to remove the burr separately.

Fine punching: Burrs will definitely be generated, and the burrs are hard burrs that must be removed through additional processes.

Differences in mold structure

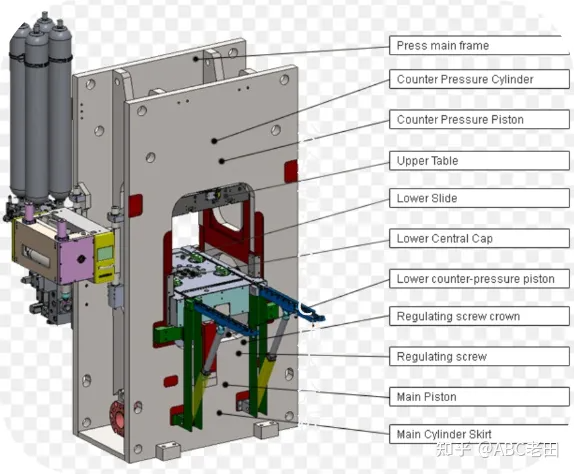

Precision punching mold is a composite mold. Unlike ordinary molds, composite molds can complete multiple forming or separating actions through one mold station in one action cycle of the press. In summary, the structure of precision punching molds has an additional ring gear pressure plate and ejector compared to ordinary stamping molds, and the gap between the convex and concave molds is very small, with rounded edges on the concave mold edge.

Use device differences

Ordinary stamping equipment generally provides unidirectional power (there are also dual power presses for processing special shaped products), that is, punching force. There are also significant differences in the tabletop, such as the length of the 800T press tabletop ranging from about 2m to about 5m. The precision punching machine can provide three power sources: cutting force, edge pressing force, and anti jacking force. Moreover, the precision punching equipment has a compact structure and a small countertop. The length of the countertop of the 800T precision punching machine is generally around 1m. Of course, like ordinary stamping machines, precision stamping machines also require other supporting auxiliary equipment. The necessary auxiliary systems for general precision punching machines include uncoiling and leveling feeder, mold lubrication system, and part waste separation system.

The main manufacturers of precision punching equipment include Feintool, ESSA, Schimid, SMG, and Osten.

The demand for low-cost in the domestic market has given rise to the existence of simple precision punching machines and precision punching mold frames. A simple precision punching machine is a common stamping machine that adds auxiliary equipment, such as oil cylinders, to achieve the function of three powers. Precision punching mold base refers to the function of precision punching achieved by adding various pressure sources to the mold on a regular stamping machine. It should be noted that this type of simple precision punching equipment cannot be used to produce products with thicker thickness or higher material strength.

03 ABC sharing meeting - post processing process for precision punching products

Unlike ordinary stamping parts, which are finished products after stamping, the precision stamping process usually accompanies a post-processing process and does not exist as a separate production process for the product. The following figure lists some common post-processing processes for precision punching. In addition to these processes, there are also processes such as leveling, grinding, and threading according to requirements.

- Deburring: As mentioned in the previous section, precision punching will inevitably produce burrs and must be removed through a process, as deburring is a necessary process.

- Machining: If the product still cannot meet the demand, further machining is required.

- Cleaning: It is necessary to clean the fine flushing oil on the product.

- Heat treatment: can improve the strength of the product.

This section will focus on the pairing of precision punching process and deburring process.

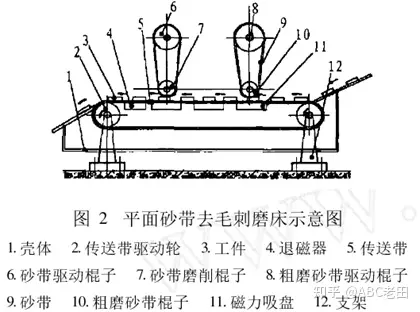

Deburring process sand belt machine

- Only for flat parts, with strong deburring ability.僅限平板件,去除毛刺能力強。

- The speed is 2-10m/min.

- Main consumables: abrasive tape, water, abrasive, rust inhibitor.

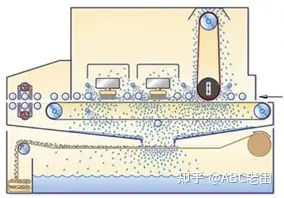

Brush machine

- Flat or non flat parts have moderate deburring ability.

- Speed 2-10m/min

- Main consumables: brush, water, abrasive, rust inhibitor.

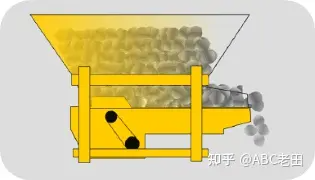

Vibration grinding machine

- Small components.

- Vibration period: 10min~60min.

- Main consumables, grinding stones, water, grinding agents, rust inhibitors.

If you are looking for related products or have any other questions, please feel free to call our sales hotline at any time

National unified sales hotline:86 514 85906288

01??Message Consultation(Equipment, output, price, materials, processes, etc)

02??Waiting for a follow-up visit(Quick response within 30 minutes)

03??Free customization(Free customization of process plans according to needs)

Want to know the price? Production? Model? After sales? Please leave a message and we will reply to you as soon as possible

MESSAGE

在線客服

在線客服